Photography by Tom Lane

Lancashire Mining Museum

Situated on the edge of Chat Moss, in an area once full of collieries, lies the picturesque village of Astley Green. In the heart of the village stands Astley Green Colliery Museum which, but for the foresight of Lancashire County Council and several leading figures within the community, would have suffered the same fate as the other collieries in the area, total demolition. It was the uniqueness of the 3,300 hp twin tandem compound steam winding engine that brought the demolition to a halt. As the result of the intervention, the museum houses Lancashire’s only surviving headgear and engine house, both of which now have scheduled monument and listed building status.

The museum occupies some fifteen acres of the Astley Green Colliery site. To the south lies the Bridgewater Canal and Astley Moss, an important mossland site. The low-lying landscape ensures that the museum’s 98ft high lattice steel headgear can be seen for many miles, a fitting memorial to days now past.

Apart from the steam winding engine and headgear the museum houses many exhibits, not least of which is the collection of 28 colliery locomotives, the largest collection of its type in the United Kingdom.

The colliery began its life in 1908 to exploit coal reserves in the south Lancashire Coalfield. Had it not been for the increasing demand for coal, at that time, the project would not have been viable. The coal seams at Astley Green are very deep and overlain by 100 feet of wet and unstable ground. These factors made the sinking of the shaft a very expensive proposition. The novelty of many of the requirements tested the ingenuity of the engineers during the construction, so much so that a paper, on the sinking of the shaft, was presented to the Institute of Mining Engineers. The colliery had a lifespan of only 62 years, finally closing its gates in 1970. Because of its short and relatively recent history, a considerable number of written and photographic records have survived. This has enabled a detailed study to be made of the construction of the colliery and its subsequent operation.

(CLICK ON IMAGES FOR ENLARGEMENT)

Above: Pictures Of The Pit Headgear

Astley Green Colliery Museum has the only surviving headgear on the Lancashire Coalfield. It is made from wrought iron lattice girders with rivetted plates at the joints. It has two large and one small wheel mounted at the top. It is nearly 30 metres (98 ft) high and was built by Head Wrightson of Stockton-on-Tees in 1910-11 for Astley Green Colliery. The sheaves were 20 ft. in diameter and the whole frame weighed 120 tons.

The site is protected as a Grade II Scheduled Monument. An English Heritage report puts the headgear in the at risk category and unless repairs and maintenance can be carried out urgently it is likely that it will be lost forever. The structure has been deemed too unsafe for access and unless sufficient funds can be obtained to repair and paint the wrought iron, the trustees feel the only alternative would be demolition. The pit closed in 1970 and in 3 years time will be the 50th anniversary of its closure. The trustees have set this as a timescale to try and preserve this iconic structure for future generations. Plans are in place to upgrade the museum to make it a centre for community activities and to provide training in various skills that are being lost.

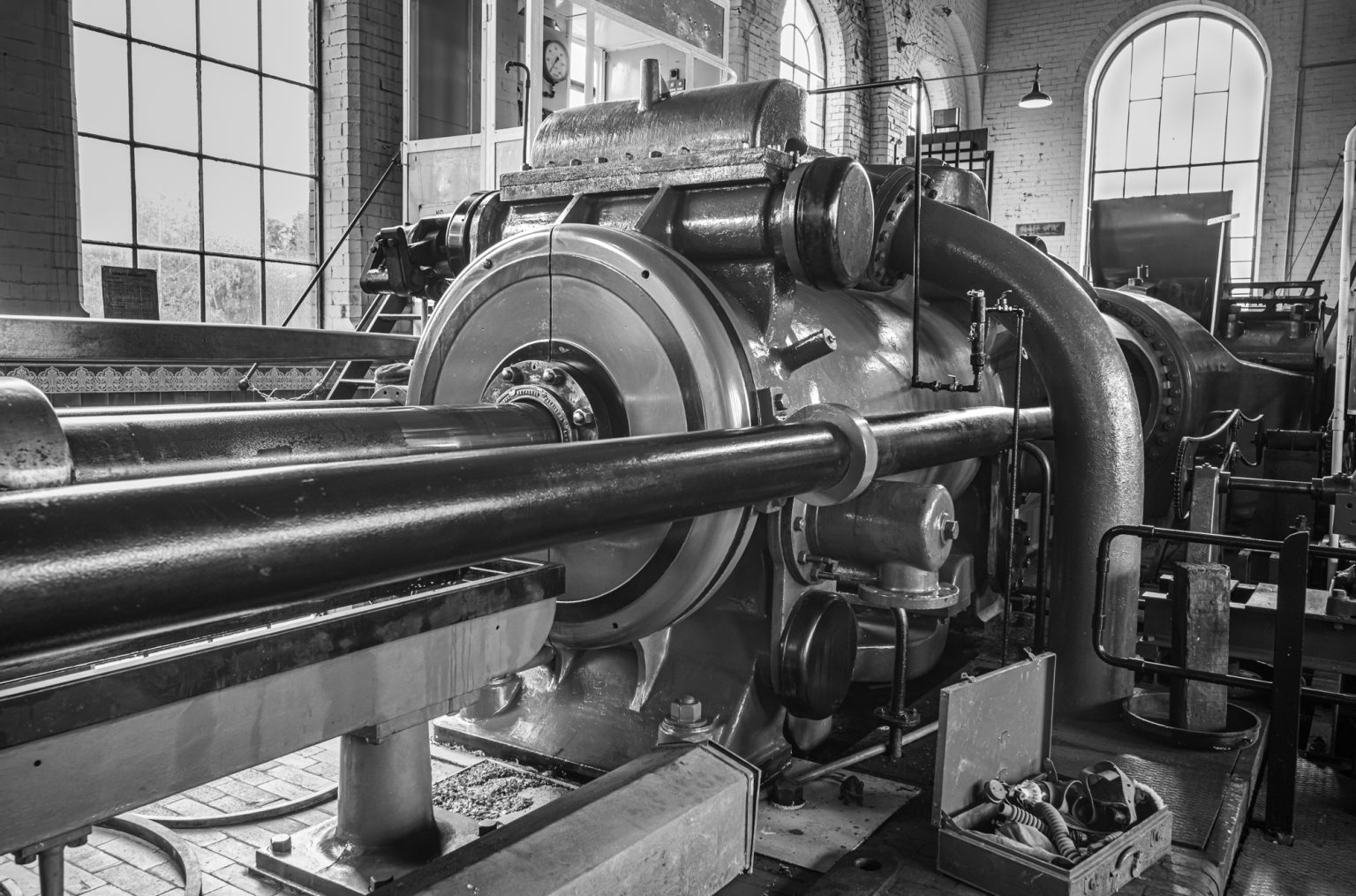

Above: Pictures Of The Engine House

The No.1 Engine house was the main building project after initial work on the shaft sinking, the roof girders were being placed in December 1910, the travelling crane of 20 ton capacity which ran along the top of the walls already being in position and in use handling the various engine parts.The engine contracts for this and the No.2 engine were let to Yates & Thom of the Canal Ironworks, Blackburn, who had also supplied the initial boilers to the site. The ancilliary gear was contracted out to Fraser & Chalmers of Erith, Kent, a G.E.C. subsidiary. The total cost for the winding house in 1910 was £4133 ( £ 400,000 today. )The winding engine was completed at a total cost of £9677 ( Approx £1.035 million today)

The winding engine which served the No 1 shaft is the largest surviving colliery winding engine of its type in Europe. It has four cylinders in twin tandem compound arrangement developing 3300 horsepower at 58 rpm. The engine was installed in 1912 and took two years to complete. It is connected to a bicylindro-conical drum which in turn was connected to the headgear pulleys to wind up the coal and wind down the miners and maintenance supplies. Most of the remainder of the colliery buildings and a second shaft with its gear have been destroyed and the winding gear is the last surviving example in the Lancashire coalfield.

Above: Re-creation of a Miner’s Cottage.

It was like trying to photograph a black cat in a coal hole.

Above: Some of the old railway locomotives which would have been used to transport coal underground.

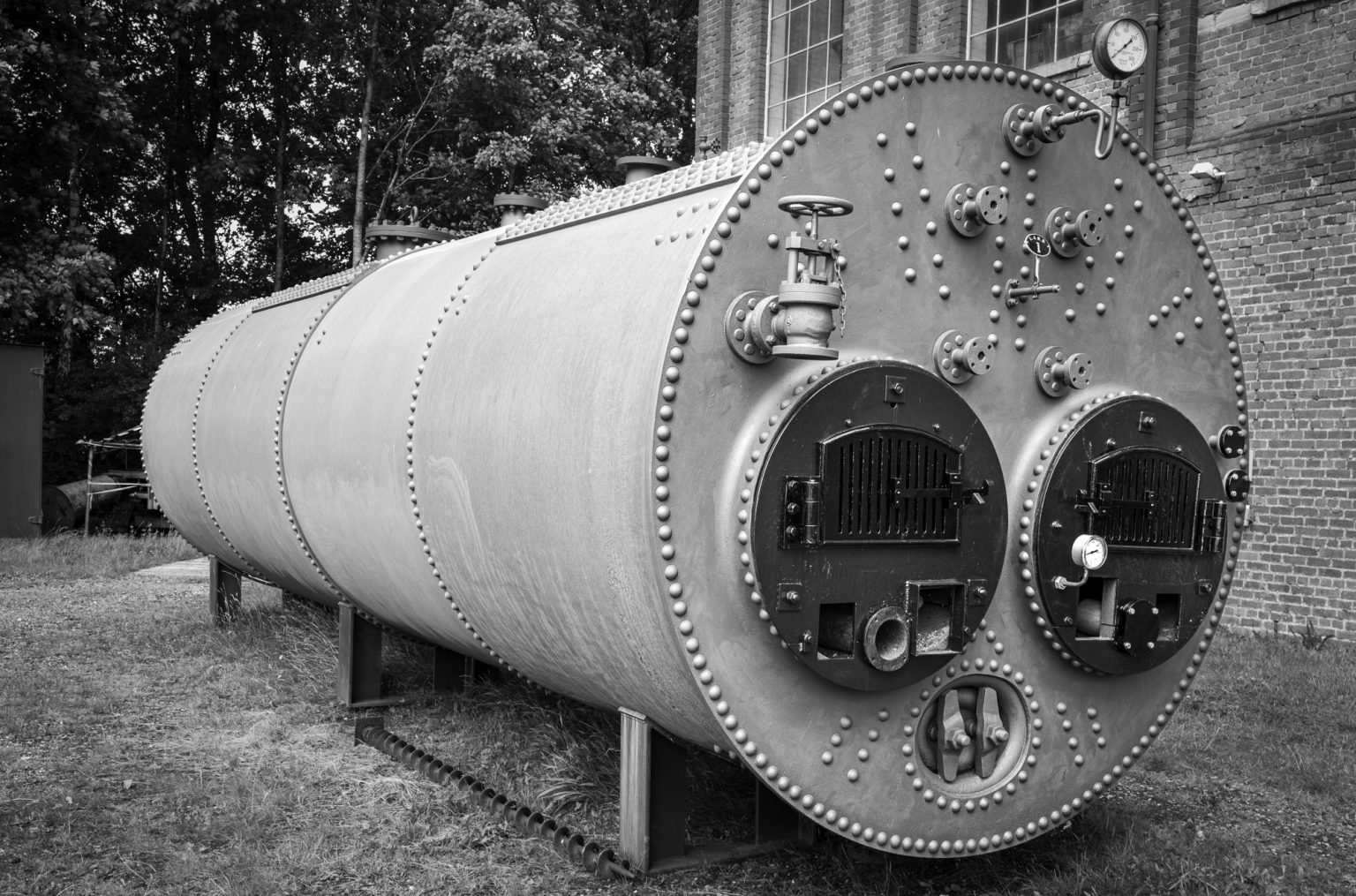

Above: Some of the old equipment found around the site yard.

Above: Just couldn’t resist taking one last image of the impressive headgear.

Photographically: All the pictures were taken with a Leica M10M Monochrom camera, which as the name suggests, only takes images in black & white, which I thought was most appropriate for this subject. I used three lenses; a 28mm, a 35mm and a 50mm, all being f2.0 Leica Summicrons.